- Guaranteed Secure Payments on Every Order

- Refund if your item is not delivered or as described

- Buyer Protection after order confirmation

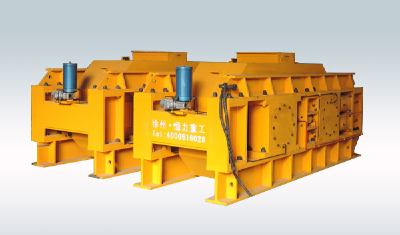

- Place of Origin: XU ZHOU

- Brand Name: HENGLI POSUIJI

- Model Number: PDG-III

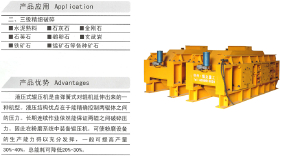

PDG- IV hydraulic pressure on the roller crusher is my company experts for many years the production of mining machinery and equipment and the wisdom of the correct decision-making. Is a with the international advanced level of high energy consumption equipment, a variety of ore crushing equipment plays an irreplaceable role in, the product widely used in cement, refractory materials, aluminum bauxite clinker, stone, diamond sand glass raw materials, building sand pebble sand and a variety of metallurgical mining industry.

Working principle

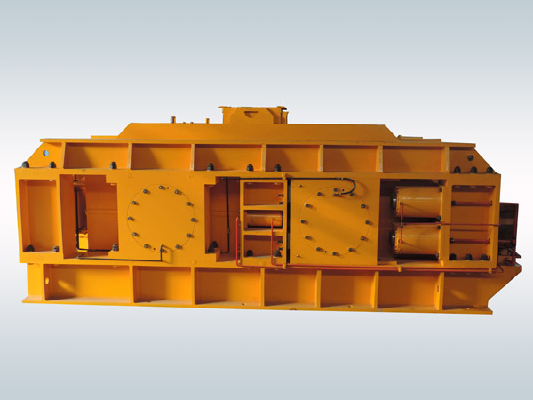

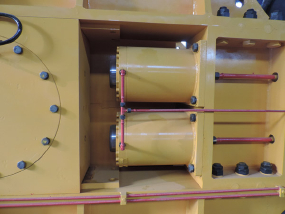

Hydraulic PDG IV of roller crusher by two opposite synchronous rotation extrusion roller, wherein, one is a fixed roller, a movable roller.

Material from the two to the top of the roller, the squeeze roller is brought into the roll, by the high pressure of 50-200MPa, the ideal size from the machine discharge.

Material from the surface of roller bit, by roller force increased gradually, discharged from the maximum pressure can reach 200Mpa. material, in addition to contain a certain proportion of powdery material and other particles in the internal, produce lots of cracks, in further crushing process can be greatly reduced low grinding energy.

Main features

In the grinding system equipment PDG- IV hydraulic pressure on the roller crusher can make the production capacity of grinding equipment to give full play to the general can improve the output 30%-40% total energy consumption can be reduced by 20%-30%.

Compact structure, light weight, small size, for the same production capacity requirements of the grinding system, equipment PDG-II on the roller crusher can significantly save investment.

The structure is simple, the occupation space is small, and the operation and maintenance are convenient.

The inner is provided with a dust proof plate, the sealing performance is good, which avoids the splashing of the broken fine material, the dust is small, the working noise is low, and the working environment is improved.

The abrasive roller body is re designed and optimized, and the equipment is used for life without changing the roller body of the mill, and the old type of the roller machine needs to be disassembled for a year.

The machine grinding roller is provided with a replaceable wear resistant lining board, and the wear resistant lining board adopts the domestic advanced wear-resistant materials, has the advantages of long service life, no easy damage, convenient maintenance, etc.. Continuous service life of up to more than one year, wear serious, move the boot cover can be replaced. Maintenance of small, low cost, which is any other type of crusher can not match the.

The machine is equipped with safety protection device, when there are unexpected metallic iron pieces into the crushing chamber, door device, iron leakage equipment normal operation.

According to the requirements of the broken particle size, the crack size can be controlled reliably, and all the particles can be discharged from the bottom of the crushing cavity, according to the requirements of the crushing granularity, and the 1mm ~ 20mm.

The structure has the advantages of simple and reasonable structure, low operation cost, stable running, high efficiency and energy saving, high crushing efficiency and adjustable discharging granularity.

This machine is the working principle of low speed and high pressure to roll extrusion. Material by crushing machine is arranged on the upper part of the vertical into broken cavity, produced by between two and strong pressure extrusion broken. Most of the material has become a powder and left inside of the small fraction of a particulate material has produced lots of cracks. In the further grinding process, the grinding energy consumption can be reduced, and the output can be improved.

- Place of Origin: XU ZHOU

- Brand Name: HENGLI POSUIJI

- Model Number: PDG-III